Adding Additive Manufacturing to Our Machine Shop

Have you ever imagined something that you wished you could build and test right away? Are you seeking an quick, inexpensive way to manufacture small run parts?

Recently we decided to step into the world of additive manufacturing by adding a 3D printer to our job shop. We’re still in the early stages of learning this new tool, but we’re very excited about what it can do to improve service at ABF. Read on to discover a few of the many of the reasons we’re bringing this modern yet basic tool into a traditional machine shop.

First, it wasn’t difficult for our staff to jump right in and start building. Many of the steps associated with CNC machining and 3D printing are similar. In both cases, a solid model and computer programming knowledge is a must. But instead of the CAM software that create the toolpaths required by model, printers use built-in “slicing” algorithms to write the code needed to build.

By their nature, printers significantly reduce waste and use less energy. In conventional machining, material is removed and discarded to create a product, while with 3D printing, material is added as the product is built. This is why 3D printing is also called additive manufacturing.

For those concerned that 3D printing creates only inferior products, modern industrial 3D printers can utilize high quality materials to produce durable, reliable products. While there are benefits to working with plastic, a high-quality 3D printer is also capable of utilizing aluminum, stainless steel, and titanium.

3D printing can stimulate the creative process, inexpensively providing a way to work through several iterations of a concept while reducing time between prototypes. The quick turn around allows you to arrive at a functional product faster than traditional forms of prototyping.

Both CNC machining and 3D printing can help shop owners keep overhead costs down by allowing us to make our own parts and repair our own machines. However, CNC machines are needed to fulfill larger and more lucrative customer orders, meaning it can be difficult and costly to find time to create individual parts for shop use.

3D printers are more efficient than CNC machines for manufacturing small quantities. Small businesses and inventors are always creating, solving problems or improving on existing products. While some small companies have the capital to afford their product’s initial creation, it doesn’t always mean that a job shop is willing to take on a small production run.

3D printers are a versatile and useful tool to add to a machine shop of any size, and we’re excited to branch into using this machinery at ABF. To find out if 3D printing might be right for your next project, email us for a quote at sales@abfeng.com.

PMPA Welcomes Melanie Webber to This Year’s Update Conference

Last week, David and Bill attended the PMPA Update Conference in Atlanta. Among this year’s many informative speakers was Melanie Webber of Fisher Phillips, an Atlanta based law firm representing employers exclusively in the areas of labor, employment, civil rights, employee benefits, and immigration law. As one the largest firms in the US, Fisher Phillps LLP has 33 offices nationwide with more than 400 attorneys.

Melanie Webber is a partner in the firm’s Cleveland office and serves as chair for the firm’s Women’s Initiative and Leadership Council. She represents and advises clients in all aspects of employment law, including harassment, discrimination, retaliation, and leave-related complaints.

Over her career, she has represented employers on traditional labor issues—such as union organizing campaigns, unfair labor practice charges and labor arbitrations

Melanie’s talk was entitled “Hiring Employees You Won’t Want to Fire,” a discussion which centered on the hiring process. Before joining Fisher Phillips, Melanie worked in Human Resource management with two Ohio manufacturing companies.

Melanie focused the conversation on how managers can develop positive, proactive employee relations programs and seek out the strong candidates who will remain as assets to the business for years to come. Throughout the discussion, Melanie provided valuable insight regarding potential human resource issues throughout the life cycle of employment.

Melanie focused the conversation on how managers can develop positive, proactive employee relations programs and seek out the strong candidates who will remain as assets to the business for years to come. Throughout the discussion, Melanie provided valuable insight regarding potential human resource issues throughout the life cycle of employment.

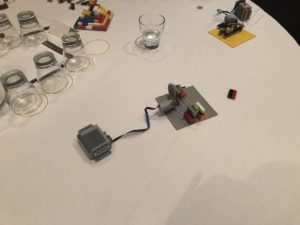

Bricks 4 Biz: Team Building with LEGOs at the PMPA Update Conference

Last week at the Precision Machined Products Association (PMPA) Update Conference in Atlanta, David and Bill had an opportunity to attend seminars, panels, and workshops relating to the machining industry; they also participated in a fun and memorable team building collaboration with other attendees, hosted by Bricks 4 Biz.

Bricks 4 Biz® is an innovative company which utilizes LEGO® to provide fun, interactive and productive team building experiences to businesses of all sizes. The company’s team oriented activities utilize LEGO® Bricks to encourage participants to overcome obstacles and challenges. Participation in the program is proven to improve communication, boost morale and develop trust and respect among a group – a powerful asset for any business to harness!

In this case, the exercise involved small teams, divided into Senior Management, Middle Management, and Workers. The focus was learning to communicate in a precise manner in order to collaborate and build a prototype without relying on drawings or other non-verbal communication.

In this case, the exercise involved small teams, divided into Senior Management, Middle Management, and Workers. The focus was learning to communicate in a precise manner in order to collaborate and build a prototype without relying on drawings or other non-verbal communication.

The ABF team had a great time laughing and sharing their struggles with other PMPA members. The end result was…interesting!

Overall, the entire conference was engaging and informative. To see more of the event, check out our second post.

Three Ways to Help Your Child Discover Robotics

Robotics is a branch of technology that deals with the making, programming, and designing of robots. For many, the definition sounds complicated and technical. Most of us don’t encounter robots in our daily lives. We think of this branch of science as something only those with advanced degrees can understand.

Nevertheless, robotics for kids remains one of the best hands-on and fun ways for children to learn STEM concepts. Even if parents cannot wrap their heads around robots and their inner workings, there is no reason why our kids cannot begin to explore the world of science through this interesting and appealing approach.

Nevertheless, robotics for kids remains one of the best hands-on and fun ways for children to learn STEM concepts. Even if parents cannot wrap their heads around robots and their inner workings, there is no reason why our kids cannot begin to explore the world of science through this interesting and appealing approach.

There are many ways to introduce children to the world of robotics without possessing the knowledge yourself; amazingly, some of these methods are both affordable and educational. Teachers and toy companies have made a parent’s job much easier; it is up to us to seize the chance to introduce our kids to a technology that can now be taught in a fun and engaging way.

There are a few things parents should know for their children to benefit from learning about robotics. Here are a few resources to help kickstart your child’s journey and improve their opportunities for success in school and beyond:

- Understand why STEM education is important and why robotics is a great way to appeal to youth. While we may struggle to wrap our brains around the batteries, wires, and conduits of robot assembly, we can learn more about the core principals so we are better enabled to guide our kids to an appreciation of mechanical concepts and the scientific process. One place to begin is STEAM Powered Family.

- Learn which robot toys, games, and apps are great educational supplements. This will allow parents to make informed and age appropriate choices when it comes to inspiring budding scientists and young engineers at home. Digital Trends has a great resource to help you find build-at-home kits. One excellent option, the Wonder Workshop has created Cue, Dot, and Dash, three programmable robots with age appropriate software to teach your children STEM concepts. For those on a budget, check out the robot app, The Robot Factory by Tinybop, available on iTunes.

- Find educational programs to provide hand-on experiences and guidance. When it comes to a truly enriching experience, a great STEM program and robotics club can really help. Programs like FIRST®LEGO® League Jr. allow children to engage in exploratory research, hands-on construction, teamwork, imagination, and fun with LEGO elements. In this program, teams of up to six students explore real-world scientific concepts, then build a motorized model and develop a Show Me Poster to illustrate their journey of discovery. Throughout the season, adult coaches provide guidance and inspiration.

Visit the FIRST LEGO League website to find a LEGO® program near you, or find out what it takes to start a robotics program in your child’s school, check out this website. Children can also learn about other kinds of machines through LEGO educational programs. You can also visit the BostonTechMom blog to discover more about robotics teams and competitions for children of all ages and interest levels.

Automating a Machining Business with David Wynn

Check out David Wynn as he discusses how to automate a machining business. One of our core values is “Automate Everything”. Humans should not be stuck doing mundane tasks. Humans should be out solving problems and doing tasks that we are uniquely qualified to do. When you have Team members running a secondary they are wasting their uniquely human talent. People need to be out creating.

Running a Machine Shop like a Tech Company

Check out David Wynn on SwarfCast. Talking about the unique way we run our company. It is all about the culture for us.

” You give them the keys to the building and a code”

Here at ABF we empower our people to be self starting. The Team knows what the numbers are and what is expected of them They know how to meet expectations. Our Team is self starters that don’t have to be told what to do. Our Team does not have to be told how to do it. The Team knows what must be done and goes out and executes.

Ep. 63 – Running a Machine Shop like a Tech Company with David Wynn

PMPA Member ABF Engineering and Machining Finds Success in its Product Quality and Internal Software Development

We were featured in an article in Production Machining Magazine. We discuss how we got started and where we are headed with the development of new technologies. Also how much a help the PMPA has been for us over the years. The PMPA has been a big factor in our success.

TS 16949:2009

After acheiving ISO 9001 certification ABF Engineering and Machining has decided to put TS16949 on our road map. In an effort to better serve our customers we plan to improve our processes and become more lean. A large part of this effort is lead time reduction to provide the best quality parts in the shortest amount of time possible. There will always be room to improve and it is that constant pursuit of perfection that will help maintain our competitiveness into the future.

ISO 9001:2008 Audit Complete

ABF Engineering and Machining has completed our stage 2 audit for pending ISO 9001:2008 certification. Once all the paperwork is complete we hope to be formally certified by the end of the fourth quarter 2013. This an exciting time at ABF as we are moving forward by having our QMS 3rd party audited for the first time. We feel that this will give us more opportunity to secure new business in the future, since ISO 9001 certification has become the gold standard for production shops in the last few years.

ISO 9001:2008 Certification

ABF Engineering and Machining is now pursuing the ISO 9001 Certification. We hope to be finished with our final audit by the end of the summer. At ABF we strive to remain customer focused at all levels of production and ISO 9001 is just the next step in making our organzation the best it can be.